How to Install Your Own Sprinkler System

Installing an in-ground sprinkler system is a big job with a big payoff.

https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=768:* 768w,https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=980:* 980w" srcset="https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=640:* 640w,/https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=768:* 768w,https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=980:* 980w" style="max-width: 100%; margin: auto; display: block; height: auto; clear: both;">

https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=768:* 768w,https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=980:* 980w" srcset="https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=640:* 640w,/https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=768:* 768w,https://hips.hearstapps.com/pop.h-cdn.co/assets/17/11/1024x683/gallery-1489524699-4670523172-3c7e5f3c90-b.jpg?resize=980:* 980w" style="max-width: 100%; margin: auto; display: block; height: auto; clear: both;">

If you're tired of dragging that old lawn sprinkler around every few days, you may want to consider installing your own underground sprinkler system. By doing the job yourself, you can save 30 to 40 percent of the cost of a professional installation, and today's sprinkler components are easier than ever to assemble. Once your system is in place, you can program it to water your lawn on a regular schedule, and also set the startup time and watering duration.

MERLE HENKENIUS

More from Popular Mechanics

First Look: 2020 iPhone SE

STEP 1: Use a gauge to determine your water pressure.

To start this process, measure your water pressure at an outdoor faucet with a simple pressure gauge available at home centers (Step 1). Then, use a 5-gal. bucket to measure how much water the system delivers per minute. Send this information to the sprinkler manufacturer you have chosen, along with a scale drawing of your property.

In return, you'll receive a system layout and a materials list, including items not sold by the manufacturer. Rain Bird, the company I used for the primary sprinkler components, has a variable fee scale for its layouts that ranges from free to $50, depending on how you want the plans delivered and how soon you need them (rainbird.com). A system layout divides your lawn into zones, each controlled by a zone valve. I installed a total of eight zones and 48 sprinkler heads.

Advertisement - Continue Reading Below

While you can install the entire system yourself and dig everything by hand, I installed the piping with a pipe-pulling machine that rented for around $180 a day.

In addition to the valves, heads and control panel from Rain Bird, I used a clever, self-tapping saddle valve called the Blazing Saddle (blazingproducts.com). This bright yellow valve snaps onto polyethylene pipe without a wrench.

In warm climates, you can run the entire system in PVC pipe. I used polyethylene pipe, a more flexible alternative, because the system has to withstand the freeze-thaw cycles that are common where I live. In any case, you must consult local plumbing codes before beginning work and you may be required to secure a building permit.

Finally, every system needs a backflow preventer to keep the sprinkler system from contaminating the potable water supply. One type is a standard, surface-level backflow preventer (about $150), which must be installed 12 in. above the highest point of the yard. I installed a reduced-pressure backflow preventer (about $350) because it's allowed below grade. I put it in the basement and will drain the system to this point each winter. The cost of an in-ground sprinkler system can vary widely. My eight-zone system ran about $1500.

Running Pipes

If you plan to dig the entire system by hand, dig the main runs first, then the branch lines. They should be at least 6 in. deep, but 8 to 10 in. will give you better fitting room.

If you've rented a pipe puller, begin by attaching the pipe to the machine's blade (Step 2). When running a main feed line, it's best to wrap the low-voltage cable around the pipe and pull it at the same time. With the piping connected, start the machine moving forward and lower the blade into the ground.

Bore through your home's rim joist, and run copper pipe and cable through the hole and to the ground. Make the conversion from copper to PVC at ground level with a threaded connector. Run the main PVC line, along with the cable, to the first zone-valve location.

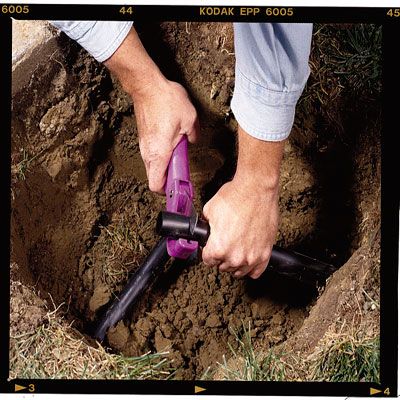

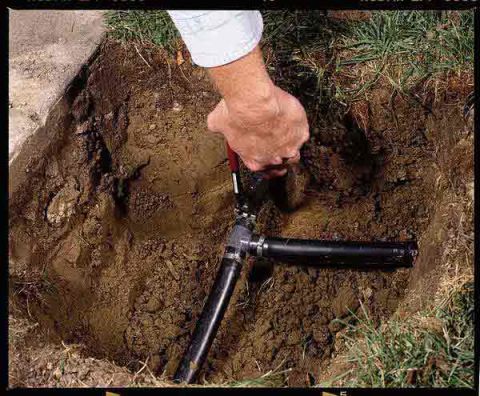

Assemble the zone-valve sets above-ground, then cement them to the underground piping (Step 3). Install a plastic, inline drain fitting on the downstream side of each valve and connect the cable wires. My cable had 10 wires and each zone valve had two lead wires. Connect one of each pair of valve lead wires to a common (white) cable wire that will service all of the valves. Join a different color-coded wire to the other lead of each zone valve. Continue making connections in this way until you've reached the last set (Step 4). With all the valves connected and wired, install valve boxes and backfill.

The feed line needs to have a drain fitting at its lowest point. Thread a brass drain fitting into the threaded end of a PVC tee and install the tee downward at 45 degrees (Step 5). Dig a small depression under the drain, and fill it with sand and gravel.

Advertisement - Continue Reading Below

MERLE HENKENIUS

STEP 2: Start the pipe puller moving forward and settle the blade into the turf. The blade will shimmy the pipe into the ground.

Merle Henkenius

STEP 3: Assemble the zone valves above-ground, then connect them to the underground pipes. Each valve needs a drain.

Merle Henkenius

Advertisement - Continue Reading Below

STEP 4: Attach one of every valve's lead wires to the white common wire and connect a colored wire to each remaining lead.

Merle Henkenius

STEP 5: Install a brass drain valve at each low spot of the feed line. Thread the valve into the tee with Teflon tape.

To tunnel under walkways and other obstacles, use a homemade sluice pipe. Attach a pointed sluice nozzle, available at home centers, to one end of a length of PVC pipe. Join a hose connector to the other end of the pipe and dig shallow trenches on opposing sides of the sidewalk. With the hose connected and the water turned on, push the pipe forward and back under the sidewalk to create the hole (Step 6).

Merle Henkenius

STEP 6: Use a sluice pipe to tunnel under sidewalks. The brass fitting is sold at hardware stores and home centers.

Polyethylene pipe is joined by barb fittings. These can be secured by hose clamps, but stainless steel crimp rings (to have a look at these, go to www.oetiker.com) are a better choice. They're inexpensive ($16 for 100) and are a snap to use. Cut the pipe with a scissors-style pipe cutter (Step 7).

Advertisement - Continue Reading Below

Merle Henkenius

STEP 7: Use a scissors-type pipe cutter on the polyethylene pipe. It's quick and easy to use, and leaves a clean edge.

Slide the crimp ring onto each pipe and insert the barb fitting (Step 8).

Merle Henkenius

STEP 8: Slide a crimp ring onto each pipe and insert the barb fitting.

Slide the rings in place and crimp them tight with the pliers (Step 9).

Advertisement - Continue Reading Below

Merle Henkenius

STEP 9: Draw the crimp rings together with crimp-ring pliers.

Installing the Heads

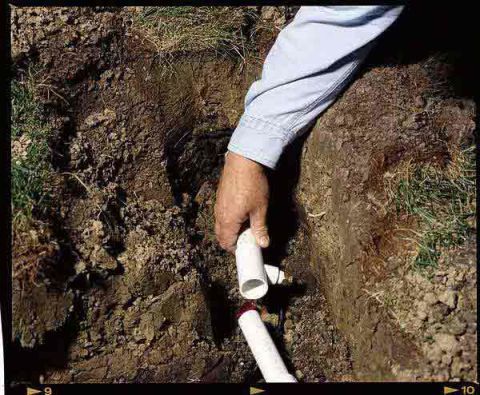

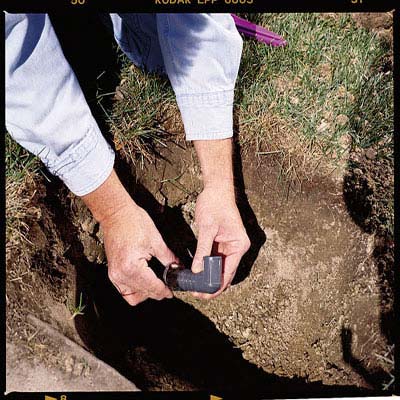

The sprinkler heads can be connected to the pipes in several ways. If drainage is not a problem, the simplest method is to install a 90-degree ell with a barb fitting on one end and a female thread on the other (Step 10).

Merle Henkenius

STEP 10: If drainage isn't required, use a 90-degree ell at the sprinkler head. Thread a riser into the top of the ell.

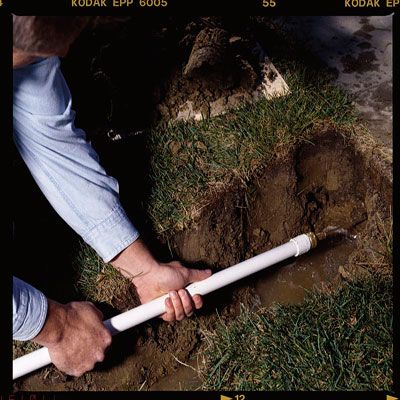

If you're at a low spot and need seasonal drainage, install a 90-degree drain ell instead (Step 11).

Merle Henkenius

Advertisement - Continue Reading Below

STEP 11: To drain a low spot under a sprinkler head, use a 90-degree drain ell. Install it upright, with the threads at the top.

From there, you can connect a head to the ell with a threaded riser, or make an offset swing pipe. To make a swing-pipe connection, thread one 90-degree ell into the drain fitting and another into the bottom of a sprinkler head. Use Teflon tape on the threads. Then, join the two ells with a length of 3/8-in. polyethylene swing pipe (Step 12).

Merle Henkenius

STEP 12: Connect the ell to the sprinkler head with 3/8-in. swing pipe. Use Teflon tape, but no crimp rings.

This fit is so snug that it doesn't need a crimp ring. Finish by filling the hole while tamping the soil with a rubber mallet every 4 in. (Step 13).

Merle Henkenius

Advertisement - Continue Reading Below

STEP 13: Backfill the hole 4 in. at a time and tamp the soil with a rubber mallet. Then top off the soil with sod.

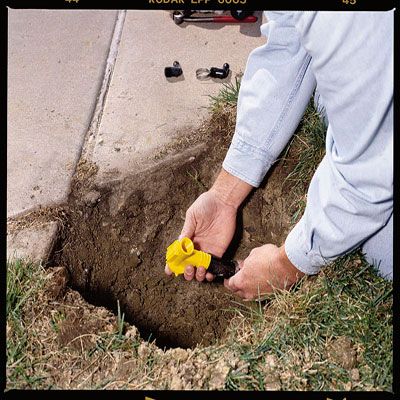

When tapping into a continuous piping run, use the self-tapping saddle valve mentioned earlier (Step 14).

Merle Henkenius

STEP 14: Press the saddle valve's collar around the pipe and snap it together. You will feel it click when it locks in place.

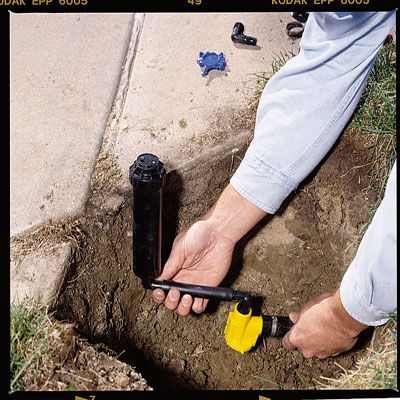

To connect the head, install either a swing pipe or a threaded riser in the top of the fitting (Step 15).

Merle Henkenius

Advertisement - Continue Reading Below

STEP 15: When the pipe is directly under a sprinkler, connect the head with a threaded riser.

I equipped my system with three types of heads: spray heads for small areas, rotary heads for the large areas and a bubbler for the flower garden. The bubbler sends a trickle of water through 1/8-in. tubing to various spots in the garden (Step 16).

Merle Henkenius

STEP 16: A bubbler head is specially designed to allow you to soak a flowerbed without getting the foliage wet.

Final Touches

Local plumbing codes will dictate how you tap into your household water system, but my installation was fairly typical. I cut into the 3/4-in. water line just beyond the meter and upsized to 1-in. pipe for the sprinkler system branch line.

Soon after the tap, install a full-flow ball valve (Step 17).

Merle Henkenius

STEP 17: Install a full-flow ball valve so you can service the backflow preventer without shutting down the house's water supply.

Advertisement - Continue Reading Below

After the ball valve, install a brass nipple and the reduced-pressure backflow preventer (Step 18). Run piping from the backflow preventer to the pipe installed through the rim joist.

Merle Henkenius

STEP 18: Install the reduced-pressure backflow preventer right after the ball valve. This type is designed for below-grade use.

This type of backflow preventer will occasionally back surge, so you'll need a catch basin with an air gap underneath it. Pipe the basin to a nearby floor drain with 1-in. pipe (Step 19). The piping after the backflow preventer will also need a drain valve so you can drain the overhead line in winter.

Merle Henkenius

STEP 19: Install an air-gap catch basin on the unit and run a full-size drainpipe to the nearest floor drain.

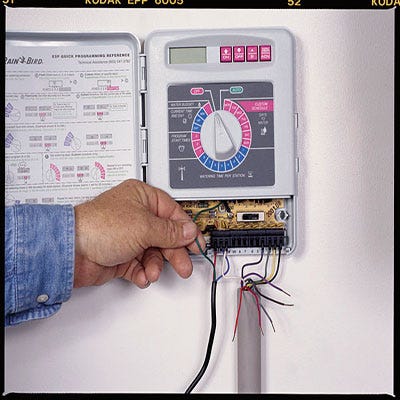

Install the control panel. Run the cable into the panel, strip the wires and connect them according to the manufacturer's installation instructions (Step 20).

Merle Henkenius

STEP 20: Run the zone-valve cable to the control box. Connect the wires according to the manufacturer's instructions.